These widely used chargers release the batch from the silo into the furnace via a vibratory conveyor.

The pusher divides the batch flow and pushes the piles into the melting area. In the stationary version, the pusher movement is always in one direction only.

There are different CPS models available, from 160 t/d to 250 t/d.

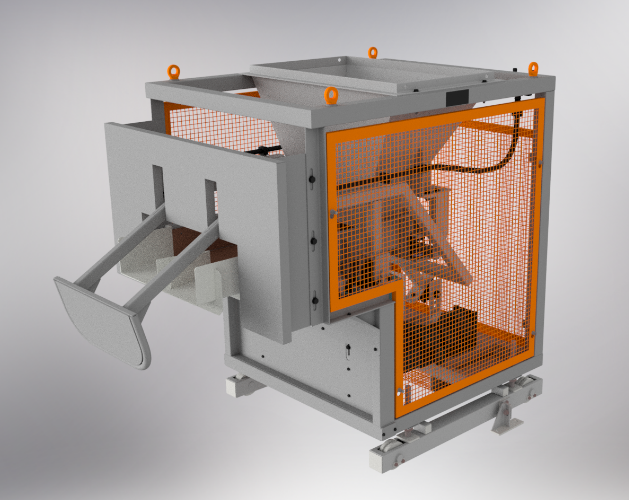

This equipment releases the batch from the silo into the furnace via a vibratory conveyor. The pusher divides the batch flow and pushes the piles into the melting area.

The oscillating version allows a swivel range of 40° with an adjustable frequency. The batch can be spread over a larger area, providing a good batch distribution into the furnace.

There are different CPO models available, from 160 t/d to 500 t/d.

A screw charger SCC is mainly used for furnaces producing special types of glass and was designed for low to medium melting rates. The incoming batch is charged from the furnace storage silo using a screw conveyor directly into the furnace.

There are different screw charger models available, from 1,5 t/d to 120 t/d.

Chute chargers with pushers and heat shields will be preferably installed on furnaces with small doghouses below the pre-furnace silo. The batch and cullet are discharged by gravity to an intermediate batch hopper on the charger. A vibrating chute, controlled by an adjustable gate, transports the batch and cullet into the doghouse. There, a water-cooled pusher moves the batch cakes into the melting furnace. EME offers various batch charger models for a variety of furnace capacities.

A wide doghouse of a float furnace needs several batch chargers. The equipment’s capacity and batch layer can be individually adjusted to optimise the batch and cullet feeding on the furnace’s melting surface.

EME Float Glass Chargers are recognised for their flexibility, performance and operation reliability, and their charging tables are individually designed to meet the doghouse’s requirements.

The EME-NEND® S Batch Charger allows for a completely sealed doghouse with relevant advantages. The batch charged from the top is conveyed to the furnace using one, two or three screw conveyors with adjustable speeds according to the required charging capacity. The subsequent pusher executes a two-dimensional movement, divides the batch into two equal piles and pushes them into the melting. The frequency of the pusher can be set variably. This allows the best possible distribution of the batch and optimises the melting process.

There are different EME-NEND® S charger models available, from 135 t/d to 480 t/d.

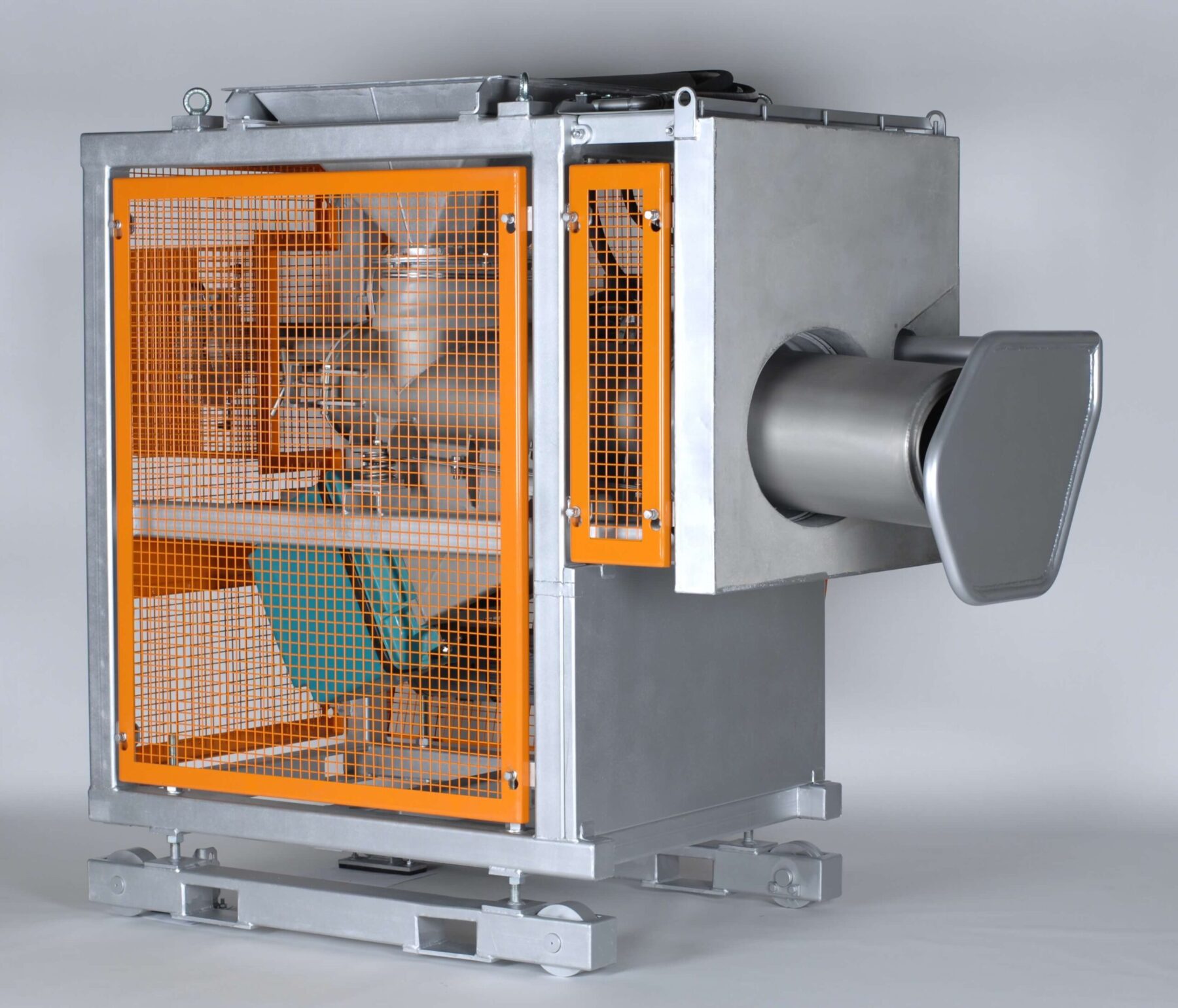

The EME-NEND® R Batch Charger allows for a completely sealed doghouse with relevant advantages. Immediately after the charge of the batch, the pusher shapes the clusters, which are then pushed forward with an elliptic movement into the melting area of the furnace.

The pusher moves and stops in front of the vibratory feeder, reducing the introduction of heat into it. A cooling jacket is put around the feeder discharge to protect it from the heat, and the feeder body is wear resistant.

The possibility of adjusting the conveying capacity of the vibratory feeder and the pusher frequency optimises the batch distribution on the glass surface.

There are different EME-NEND® R charger models available, from 50 t/d to 500 t/d.

The EME-NEND® VL/VR Batch Charger allows for a completely sealed doghouse with relevant advantages. This equipment can be used both on a standard doghouse and on an IRD doghouse. Due to its modular design, melt capacities from 85 t/d to 500 t/d (2×250 t/d) on two machines next to each other (VL and VR) can be achieved.

Immediately after the insertion of the batch, the pusher shapes the clusters, pushing them into the melting area of the furnace with a linear movement. The pusher then stops in front of the vibratory tube and reduces the introduction of heat into it. The possibility of adjusting the conveying capacity of the vibratory feeder and the pusher frequency optimises the batch distribution on the glass surface.