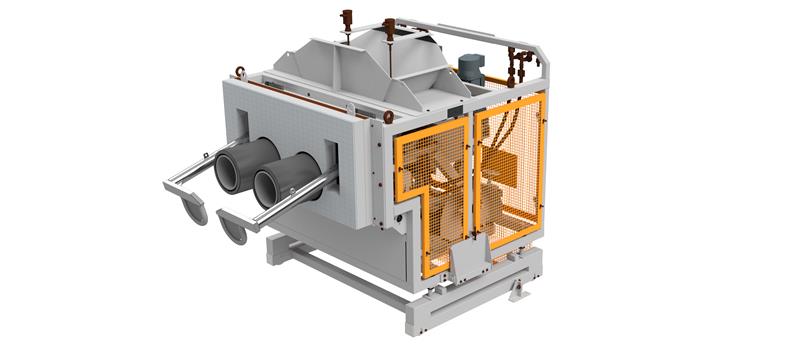

The next generation Batch Charger is setting new standards in performance, energy efficiency and maintenance.

Building on the EME-NEND® product family, our new EME- NEND 2 Flex is one of the most advanced batch charging systems available today.

With a 20% lighter frame than previous models, insulation material in the heat shield and a removable protective grid, the EME-NEND 2 Flex combines structural strength with improved handling, improved efficiency and simpler maintenance.

Optimised Screw System

The screw conveyors are now centrally aligned, minimising the machine’s footprint while enhancing accessibility and batch flow. The advanced screw oscillation offers time-adjustable delivery rates with customisable oscillation cycles providing greater control over the material feed.

Dual Independent Pushers with Servo Technology

Particularly noteworthy are the two independently controlled pushers, each driven by a servo gearbox, for enhanced precision and adaptability. For maximum flexibility operators can choose from three programmable modes:

- Batch Cutting: run independently and wait at designated intervals for each other

- Synchronous Mode: pushers move in unison for standard operations

- Independent Mode: pushers operate separately for custom melting profiles

User-Centric Adjustability and Maintenance

Operators can fine-tune pusher settings without having to take any of the machinery apart, and the side-mounted pusher design further reduces downtime by providing easier maintenance access.

Advanced Control System

The Siemens TIA-CPU 150 with integrated web-based control access, providing secure remote operation and diagnostics. A new 12” touch panel allows operators to switch between different parameter sets to accommodate variations in batch compositions, recipe management and melting needs.

A Smarter, More Flexible Future for Batch Charging

With EME-NEND 2 Flex EME underlines its commitment to completely sealed doghouse operation, ensuring minimal emissions, less dust and greater overall furnace efficiency.