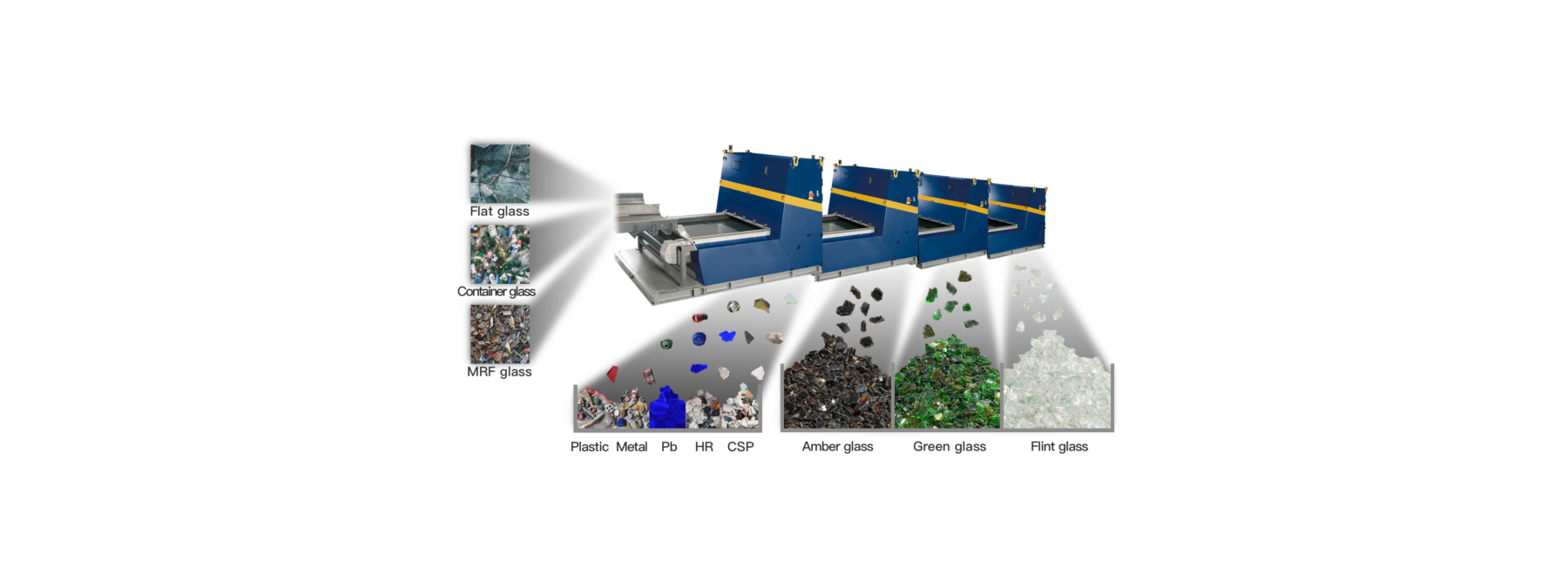

Optical sorters detect and separate off-colours, CSP (ceramics, stones, porcelain), plastics, HR (heat resistant) and PB (lead) glasses. EME offers optical sorters, belt conveyor separators, and free-fall systems with high detection accuracies and precise separation. The sorters are suitable for dry and wet material and have a modular multi-sensor system.