OUR RESPONSIBILITY

SUSTAINABILITY AND FUTURE-ORIENTATION

Environmental protection has gained increasing importance and relevance in recent years due to climate change.

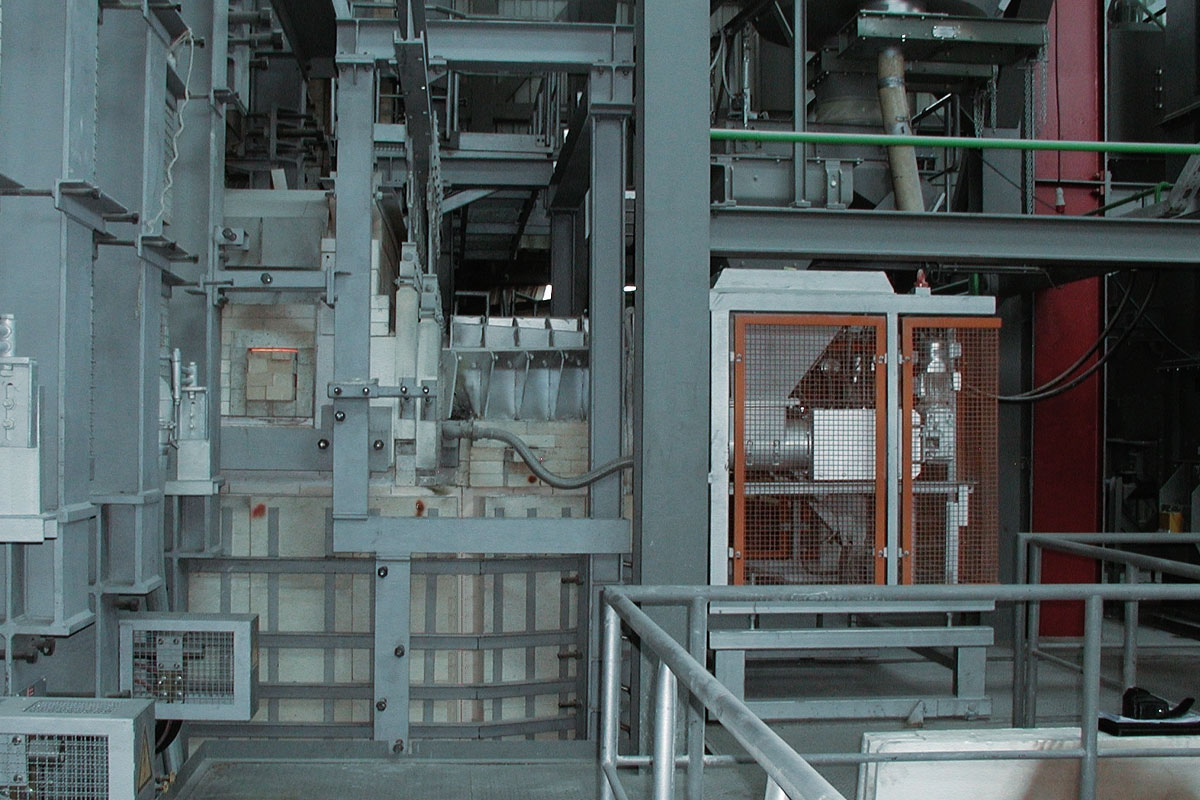

As a company, EME has a special obligation to act sustainably and with a future-oriented approach. To fulfill our responsibilities to our customers, suppliers, employees, and the environment, we have decided to integrate environmental protection into our existing management system alongside safety and quality.

Read More